Driveline Service: What's the "diff"erence?

Driveline, A.K.A drivetrain, service is easy to overlook. Driveline components are located under your vehicle and are easy to ignore. Making proper inspection and maintenance vital to the reliability and longevity of your vehicle. Failure to maintain these systems can lead to unneeded expense and downtime. The good news is most of these systems will last the life of the vehicle with proper maintenance. You can find the specific maintenance intervals for your vehicle in the owner’s manual. Remember to look at the “Severe Use” maintenance schedule. For more information as to why, see our BLOG from March 2024 “What do I need to know about Interval Service of my vehicle?” Let’s discuss each component and the industry’s best maintenance practices for each.

- Automatic Transmission: Automatic transmissions can be very costly to repair or replace. Regular maintenance is vital to the long life of your transmission and the fluid is the key. The transmission fluid cools, lubricates, and pressurized fluid does the work of shifting gears. Heat is the nemesis of your fluid. Heat causes the fluid to breakdown and stop doing its job of lubricating your internal transmission parts. Which leads to transmission failure. Regular fluid exchanges maintain and extend the life of the transmission by replacing the degraded fluid and removing containments suspended in the fluid from clutch wear. Manufacturers recommend fluid exchanges from 30,000 to 60,000 miles depending on the vehicle and how it is used. Do you do lots of towing? How about heavy hauling? Or maybe you live down in Florida or Arizona in the winter? All of those are great reasons to service your transmission on a more regular basis.

- CVT Transmissions: Continuously Variable Transmissions differ from regular automatic transmissions in that they don’t shift gears as the vehicle accelerates. Most of them use several pulleys with a chain. The pulleys can change in diameter, which changes the final drive ratio. This is done by allowing and controlling chain slip on the pulleys. Which produces heat and breaks down the fluid. The harder you drive these cars, the faster the fluid breaks down. Some manufacturers will say they are “Lifetime filled” and do not require service. That works if you want to shorten the “life” of your transmission. Most of the time these will be found in smaller, lighter vehicles in the hopes of squeezing out better MPG. Which works if you drive them easy and service the fluid regularly. The best practice is to service the fluid every 30,000-60,000 miles.

- Manual Transmission: Believe it or not, there are still a few vehicles running around town with manual transmissions. Normal service intervals are 30,000-50,000 miles for the transmission fluid and every 2-3 years for the hydraulic clutch fluid.

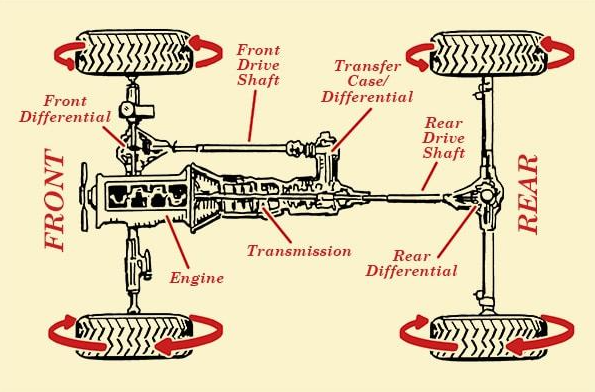

- Front and Rear Differentials (Axles): The differentials allow for smooth transmission of power to the wheels while turning. Usually found in larger cars (rear) and trucks (front and rear). Quality fluid is the only thing that keeps the gears from self-destructing when the gear teeth are sliding alongside each other when moving. Recommend service intervals of 30,000 to 50,000 miles. The harder you work them, the more often the fluid should be changed.

- Transfer Case: If your vehicle has four-wheel drive (4WD) or all-wheel drive (AWD), it will have some kind of transfer case to distribute the power to all four wheels. Most 4WD trucks and SUVs will have a transfer case with high and low range. AWD vehicles may have a transfer case, a viscus coupler, or power transfer unit. All perform a similar function, to distribute the power to the other axle. All will have some kind of fluid to lubricate them and cool the gears. Recommend service intervals are 30,000 to 50,000 miles. The key factor is to use the correct fluid when servicing.

- Driveshafts and U-joints: Most trucks with 4WD use driveshafts to distribute the power to the differentials. U-joints allow those driveshafts to flex with the suspension oscillations. Some u-joints are greaseable. If they are, then they need to be greased with every oil change. Failure to do so can cause them to fail, which can cause significant damage to the underside of the vehicle. We recently had a customer with a u-joint failure that led to the transfer case breaking in half. The gears from the transfer case, attached to the front driveshaft, decimated the underside of the vehicle. Pounding holes in the floor and tearing out the wiring and fuel line under the truck. The cost to repair the damage was over $11,000. Greasing and replacing failing u-joints can prevent damage like this. Make sure your service center is maintaining these critical components.

- Wheel Bearings: Wheel bearings have evolved over time. In the past, most were greaseable and required regular service. Now, most of them are sealed and just need replacement when they reach the end of their service life. Inspection during service and listening for increased road noises when driving is the best way to identify a sealed wheel bearing that is starting to fail. A humming noise that increases with road speed sometimes indicates a wheel bearing that is failing.

- CV Axles: Constant Velocity axles are found in many front wheel drive vehicles, AWD, and 4WD vehicles. They are usually found on steering axles and vehicles with independent suspension systems, allowing them to power, turn, and ocellate the wheel at the same time. The only maintenance is to inspect the boots periodically. If the boots are leaking grease, then the axle shaft assembly needs to be replaced.

As you can see, there are quite a few components under the vehicle that need periodic inspection and maintenance. Regular service saves you money by preventing unnecessary replacement. All components that use fluid for lubrication and operation will need period fluid service. Which is removing all the old fluid and trapped contaminants and replacing it with fresh new, correct application, fluid. Some fluid services use a cleaner before the service to help suspend contaminants in the fluid, so they can be removed during service. Finding a qualified and reputable service center can help identify when services are needed and take care of them at the appropriate time. At Sanderson Auto Repair, we check and test all vehicle fluids annually, at no additional cost to the customer, to help identify when they need service or replacement. Spending a little money on service now is always less expensive the replacing costly parts and components in the long run.

Aaron B.