What to Know About Lift Kits and Suspension Modifications

Is your stock vehicle just begging you for bigger tires and a lifted suspension! I get it. Some vehicles just look wrong when left in stock form. Especially when vehicles with big tires are everywhere once you start looking for them. It seems like it would be an easy thing to order up a lift kit and a set of big tires so you can be the coolest cat on the block! Just Google a lift kit for your truck and many options will likely pop up. Some of those options are much better than others. Do you know what to look for and what to stay away from? Well, you’re in luck because that’s exactly what we are going to talk about here. When you know the right questions to ask, you can ensure that you don’t end up wreaking a perfectly good vehicle and turning it into something you hate to drive. In most cases, vehicle suspension modifications will be required to fit those big tires under the vehicle. Vehicle manufacturers spend a lot of time and money dialing in your vehicle’s suspension, so it rides smoothly, handles predictably, carries the load, and remains reliable throughout the vehicles’ service life. Making changes, even minor ones, to your vehicle suspension can have dramatic effects on the handling and performance of your vehicle. By answering the questions below, you can ensure that the final result performs as good as it looks.

- What do you plan to do with this vehicle? Is it a daily driver? Weekend adventurer? Trail only vehicle? Do you regularly drive the vehicle at highway speeds of 60 MPH and above? Knowing how you plan to use the vehicle is a very important step to success. Vehicle suspension systems need to be engineered properly and consider many factors like the vehicle's center of gravity, suspension angle changes during oscillation, and weight transfer. Overlooking those key considerations creates a vehicle that can be dangerous and quirky to drive at any speed over 40 MPH.

- How big of a tire do you truly need to accomplish your goal? Are you starting with a vehicle on 32" tires and you would like to bump them up to 35" or are you going straight to 40" tires and above? Your vehicle was designed around a specific tire size. Keeping the increased tire diameter within 10% of the factory tire size is usually within the vehicles "area of tolerance". Meaning, it doesn’t usually require significant vehicle modifications to accomplish, and it is less detrimental to the vehicle braking, steering, suspension, axle, and drivetrain systems. The more the vehicle strays from stock form, the more modifications are required to fit the larger tires and maintain vehicle reliability. When systems and components are forced to operate out of their designed parameters, they will begin to fail. Forcing you to replace or upgrade many other components to keep the vehicle together and on the road.

- Spend the money on a properly engineered system. While it may be tempting to try to save money by installing a budget-friendly lift to fit those awesome new wheels and tires. Resist the temptation! Properly engineered suspension systems can be expensive because of the time it takes to design them, test them, and certify them compliant with FMVSS (Federal Motor Vehicle Safety Standards). If you plan on driving the vehicle on the street, stay away from all lifts labeled as "off-road use only". Those kits may save you some money but will likely cause adverse handling characteristics to your vehicle.

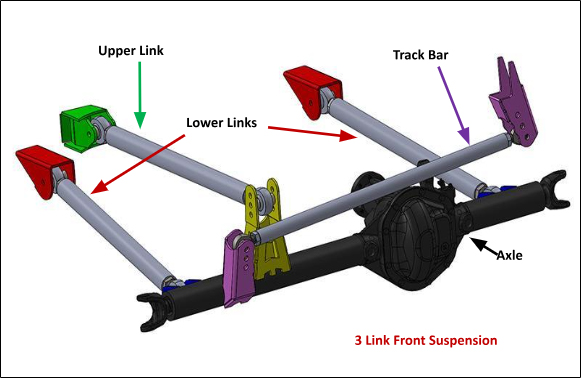

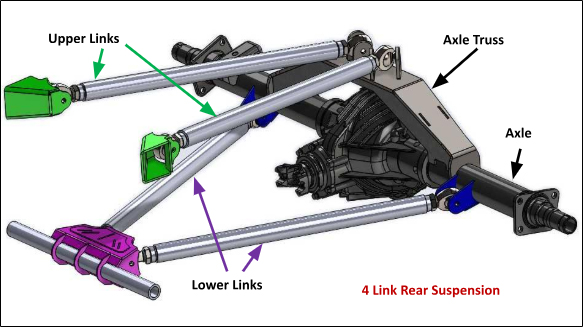

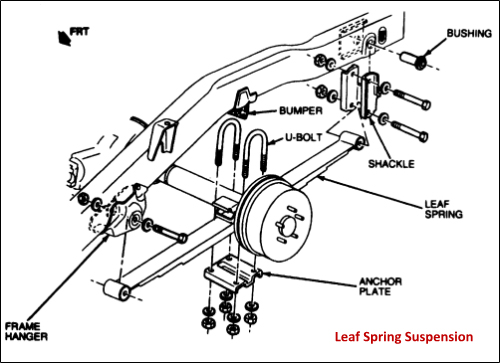

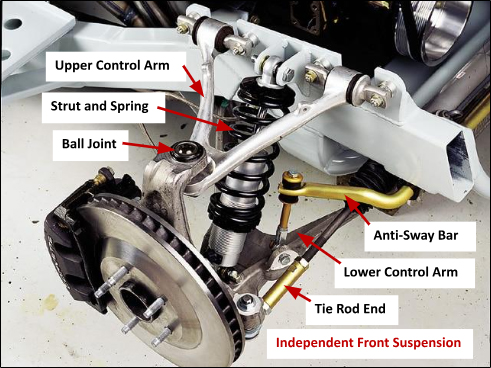

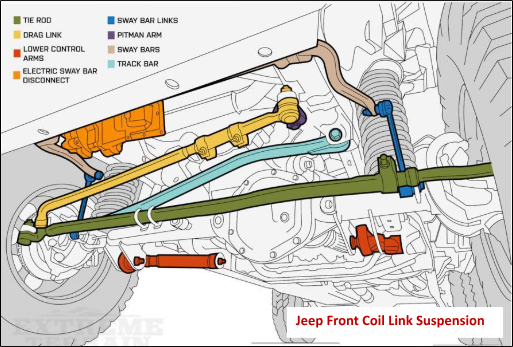

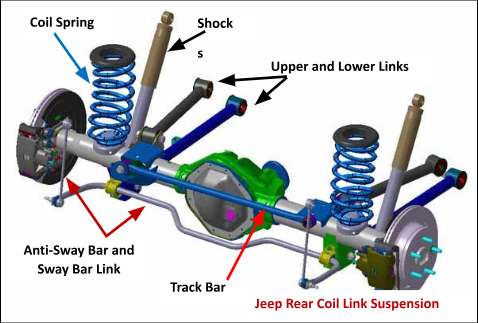

Let's check out some real-world examples of vehicles modified to fit larger tires. They vary from budget builds to custom builds and really highlight the points above. Before we dive into the builds, let's clarify some of the vehicle terminology so it makes more sense. These are common suspension systems found on vehicles that are likely modified to fit larger tires.

First, we have a 1993 Jeep Grand Cherokee. Very rusty and somewhat trusty. Build goal: fit larger used tires and wheels to save money to make the vehicle street drivable. I picked this vehicle up for a low cost so my daughter could learn how to do mechanical repairs to keep a vehicle running. It's a spare vehicle that I do not want to invest much money in. The vehicle really needed new tires to make it safe to drive on the street, but I really didn't want to spend the money on a new set of tiny stock sized tires. I just happened to have a set of takeoff wheels and tires from my 2010 Jeep Wrangler. These 32" tires are about 13% larger than the stock 28" tires. They were too big to fit on the stock height vehicle and the wheels had the wrong bolt pattern. So, I sourced a quality but economical 3.5" lift kit from Iron Rock Off-Road for less than a set of new stock sized tires. The lift kit came with new longer shocks, sway bar links, front coil springs, and adjustable front track bar. The original factory front coil springs got moved to the back of the vehicle, which provides the rear lift and new springs in the front. I then added a set of wheel spacers to change the vehicle wheel bolt pattern to match the "new" wheels. The result is a vehicle that mostly fits the tires and has some driving quirks due to the 3.5" lift. These vehicles use coil springs front and rear with links to locate the axles under the vehicle and control axle movement. Suspension links work best when they are parallel with the ground, allowing the axle to move up and down with minimal forward to back movement. Lifting the vehicle with the stock short links causes them to operate at an angle compared to the ground. This causes the axles to move forward and back as they move up and down. Look at the picture above and see how the rear axle is pushed forward and not centered in the rear wheel well. This kit also utilized the stock rear track bar, which moved the rear axle to the passenger side as it was lifted, causing the rear of the vehicle to wobble back and forth when you hit bumps due to the angle of the track bar. The Iron Rock Off-Road kit is designed to be an economical, entry level starter kit. With the idea that you will add to it over time to improve the vehicle performance and handling. It gets the job done, but they have many options available that offer much improved overall performance. Yes, the larger tires fit, but the driving quirks make the vehicle uncomfortable for most people to drive.

Next, we have a 2022 Jeep Wrangler Unlimited Sahara with 37" tires and a Metalcloak 3.5" Game Changer lift and 6pak shocks. Steer Smarts XD Pro track bars front and rear, and sector shaft steering gear box reinforcement bracket. Build goal: build a vehicle that can be used as a daily driver and handle off-road exploration and driving. The 37" tires are about a 15% larger tire than stock. The Metalcloak Game Changer kit is an engineered full suspension system. It replaces many of the factory components with ones specifically designed for the additional ride height. It utilizes longer suspension links and new mounting locations designed to keep the links in a more horizontal location. This vehicle drives down the road with the reliability and predictability of a factory designed suspension and can tackle most off-road trails with finesse and precision. It provides impressive flex on the trail as it slinks over obstacles. Overall, it is a joy to drive, has handled some impressively gnarly terrain over the years, and continues to be a reliable daily driver. A real testament to a well thought out, thoroughly tested, and impressive complete suspension solution.

Finally, we have a 1985 Jeep CJ-7 with 40" tires and a fully custom coil spring link suspension. Build goal: build a vehicle capable of tackling fun off-road trails while still being safe to drive down the Interstate. Not a daily driver. You're looking at version three of this vehicle. It first went from 29" tires to 33" tires using a 4" leaf spring suspension lift. Then, I bumped it up to 35" tires on the same lift. After rolling the vehicle, I decided to start from scratch and design a custom link suspension to fit 40" tires. The 40" tires are about 40% larger than the stock 29" tires. As you can imagine, a 40% increase in tire size requires extensive vehicle modifications to control the strain of the larger and heavier wheels and tires. The complete vehicle drivetrain, (engine, transmission, transfer case, driveshafts, and axles) was upgraded or completely replaced during the build process. Very few stock vehicle components remain in this Jeep build. It was my first attempt at designing and building a suspension system from the ground up. I spent two years researching and designing the suspension for this vehicle with many revisions along the way. Packaging a custom suspension within the confines of a frame and drivetrain is challenging. I wanted to go with more traditional coil springs and separate shocks instead of the more prevalent coil over suspension designs to keep the on-road driving characteristics more consistent and predictable. As I mentioned previously, minor suspension changes can have a dramatic effect on how the vehicle handles and operates. By taking my time and thoroughly researching, designing, and fine tuning the suspension, the vehicle suspension operates very predictably and drives down the road smoothly and safely. I would make some additional adjustments to the design if I did it over again, but it functions very well, and I have been pleased with the overall performance.

Recommend Manufacturers

Complete Suspension System Manufacturers

Quality Builder Kit Manufacturers

Builder Part Manufacturers for custom suspensions

Installing larger tires and a suspension lift on your vehicle can be a very exciting experience. Follow the steps above to end up with a vehicle that performs as good as it looks. If you plan to drive it on the street, invest in a properly designed and engineered suspension system. Keep the increased tire size to within 10% of the original tire size if you would like to maintain the reliability of the rest of the vehicle. Be prepared to upgrade most of the suspension, drivetrain, brake, and steering components should you decide to go above the 10% increase in tire diameter. The next weakest link down the line will always reveal itself at the most unexpected times. If you are building a trail-only vehicle, take the time to do some research to understand how your proposed suspension system should work. Be aware of the effects of packaging compromises around the vehicle frame, drivetrain, and other vehicle mounted components. I've seen some home-built suspensions that are dangerous and unpredictable, and I've seen some that are a marvel of redneck engineering. There are many trails out there just begging to be explored! Taking the time to do the research before the build and using quality components and properly designed systems will keep you moving on the trail and exploring instead of broke down watching your buddies have all of the fun.

Aaron Bjorklund